Walking into a beautifully tiled space, whether it’s a grand hotel lobby or a cozy kitchen, always sparks a sense of awe. The intricate patterns, elegant color palettes, and captivating textures create a visual symphony that transforms any environment. But have you ever stopped to wonder about the journey these tiles take, from initial inspiration to their final placement on the floor? It’s a fascinating process involving creativity, precision, and a whole lot of expertise.

Image: lasepattern.net

This journey begins with ceramic tile companies, the unsung heroes behind the stunning floors we admire. They are the architects of style, weaving together artistry and industrialization to craft unique and functional tiles that define spaces. In this article, we’ll delve into the world of ceramic tile companies, exploring their design process, manufacturing techniques, and the impact they have on our homes and businesses.

From Inspiration to Tile: The Design Process

The design of a ceramic tile is more than just aesthetics; it’s a careful consideration of functionality, durability, and the overall design theme. Ceramic tile companies employ teams of skilled designers who translate trends, customer preferences, and even architectural styles into tangible tile designs. The process often involves:

1. Trend Research

Like any industry, the ceramic tile industry is constantly evolving. Designers stay ahead of the curve by researching emerging trends in interior design, architecture, and even fashion. They analyze popular color palettes, patterns, and materials to understand what’s capturing the public’s imagination.

2. Concept Development

Armed with trend insights, designers begin developing initial concepts. This involves brainstorming ideas, sketching designs, and exploring different materials and finishes. The goal is to create a diverse range of tile options that cater to different styles and preferences.

Image: www.pinterest.com.mx

3. Prototyping

Once a concept is finalized, it moves into the prototyping phase. This involves creating small-scale samples of the tile using various ceramic materials and glazes. Designers use these prototypes to refine the design, experiment with different textures, and ensure the final product meets their vision.

4. Digital Modeling

Today, technology plays a crucial role in the design process. Designers utilize software tools to create 3D models of the tile, allowing them to visualize the final product in a realistic setting. This digital approach helps ensure the design is harmonious with the intended space.

5. Testing and Refinement

Before a tile design goes into full-scale production, it undergoes rigorous testing. This ensures the tile is durable, scratch-resistant, and meets industry standards for safety and performance. If necessary, designers make final adjustments based on the testing results.

The Art of Manufacturing: A Look Behind the Scenes

Once the design is perfected, the production process takes over. This is a highly technical aspect of tile creation, involving specialized machinery and skilled technicians. The steps generally include:

1. Material Preparation

Ceramic tile production begins with the preparation of raw materials, including clay, feldspar, and quartz. These materials are carefully weighed, blended, and then ground into a fine powder called “slip.” The quality and consistency of the slip are critical for producing tiles with uniform properties.

2. Molding and Shaping

The slip is then poured into molds, which define the shape and size of the tile. Techniques like pressing, extrusion, or casting are employed depending on the desired tile profile. A key step in this stage is ensuring the molded tile is perfectly flat and free of defects.

3. Drying and Glazing

The molded tiles are then dried in controlled environments to remove moisture. This prevents cracking and ensures structural integrity. Once dry, the tiles are glazed, applying a thin layer of colored glass that gives them their unique appearance. Glazes can be applied by dipping, spraying, or printing, allowing for diverse patterns and finishes.

4. Firing

The glazed tiles are then fired in high-temperature ovens, known as kilns. The heat transforms the ceramic materials, fusing the glaze to the tile surface while also hardening it. The firing process is crucial for achieving the desired durability, water resistance, and strength of the tiles.

5. Quality Control

To ensure consistency and quality, each batch of tiles undergoes rigorous inspection. Trained professionals examine the tiles for defects, color variation, and adherence to design specifications. Defective tiles are discarded, while those that pass are sorted and packaged for distribution.

Trends in Ceramic Floor Tiles: A View of the Future

The ceramic tile industry is constantly evolving, driven by design innovation, technological advancements, and ever-changing consumer preferences. Here are some key trends shaping the future of ceramic floor tiles:

1. Large Format Tiles

Larger format tiles are gaining popularity, offering a clean and minimalist aesthetic. These tiles, measuring over 12 inches in size, can make spaces appear more spacious and seamless.

2. Natural Textures

Mimicking the beauty of natural materials, like wood, stone, and even textiles, is a growing trend. This allows homeowners to achieve a specific design theme without using expensive and high-maintenance materials like real wood.

3. Sustainable Materials

Environmental consciousness is influencing tile production. Companies are using recycled materials, reducing energy consumption, and developing eco-friendly processes to minimize their environmental footprint.

4. Smart Tile Technologies

The integration of technology is opening new possibilities. Companies are creating tiles with features like embedded lighting, heating, and even touch-sensitive surfaces, transforming floors into interactive spaces.

Tips and Expert Advice for Choosing Ceramic Floor Tiles

Choosing the right ceramic floor tiles for your home or business can be a daunting task. Here are some tips to help you navigate the process and make informed decisions:

1. Define Your Needs

Start by considering the purpose of the space and your personal style. Do you need durable and moisture-resistant tiles for a bathroom, or are you looking for elegant and decorative tiles for a living room?

2. Consider Foot Traffic

Choose tiles with appropriate resistance for the level of foot traffic. High-traffic areas like entryways and kitchens may require more durable tiles than bedrooms or guest rooms.

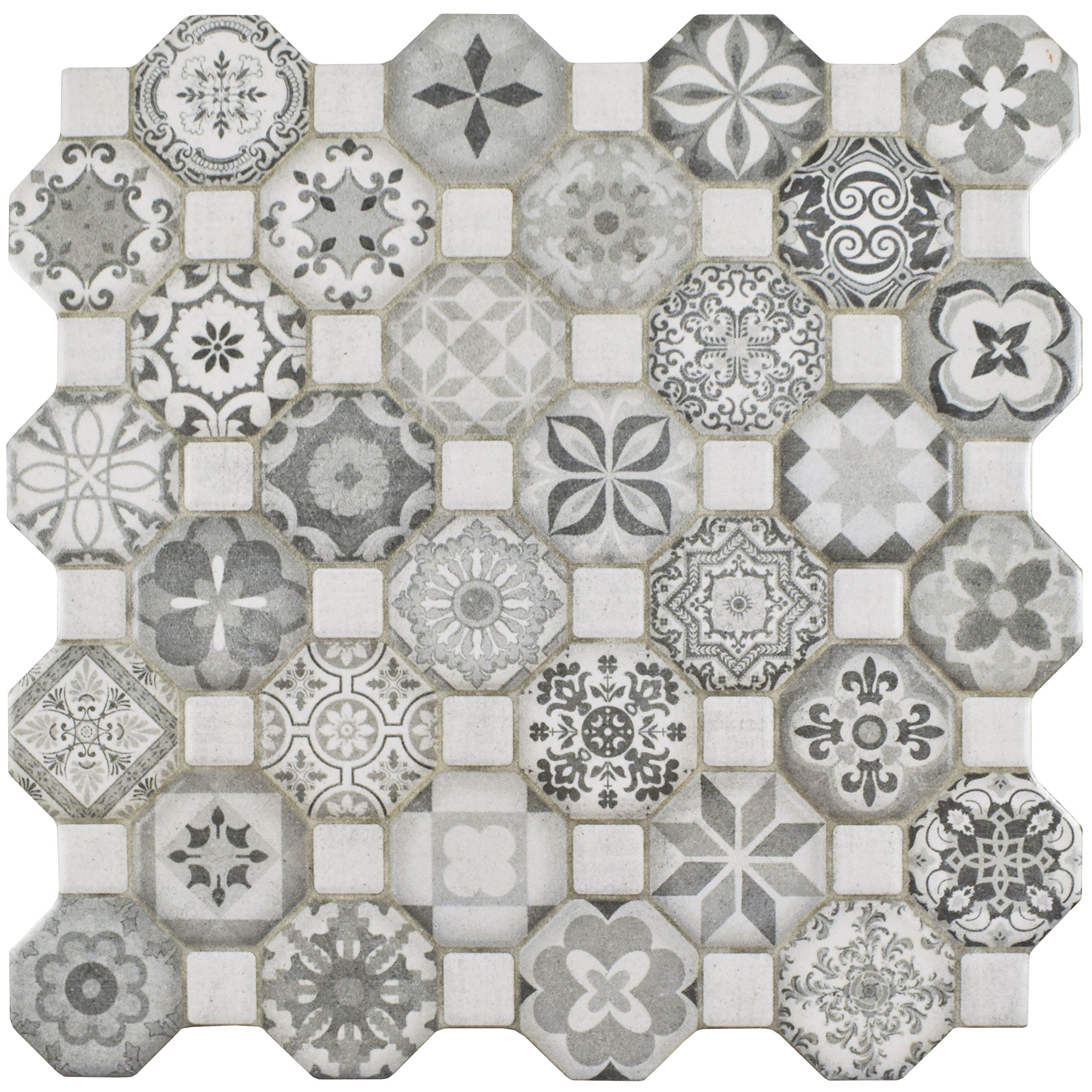

3. Explore Tile Shapes and Layouts

Experiment with different shapes and layouts to find a pattern that complements your space. Square and rectangular tiles offer a classic look, while hexagonal and mosaic tiles add a more intricate touch.

4. Research Tile Maintenance

Different tile materials require different cleaning and maintenance routines. Select tiles that align with your lifestyle and cleaning preferences.

5. Consult a Specialist

Don’t be afraid to seek professional advice. Ceramic tile specialists can help you select the right tiles for your project and provide insights on installation techniques.

Frequently Asked Questions (FAQs)

Q: What is the difference between ceramic and porcelain tiles?

Both ceramic and porcelain tiles are made from clay, but porcelain tiles are fired at a higher temperature, resulting in a denser and more durable product. Porcelain tiles are also generally less porous, making them ideal for high-moisture areas like bathrooms and kitchens.

Q: How do I know if a ceramic tile is suitable for my project?

Look for information about the tile’s wear rating, which indicates its resistance to abrasion and scratching. Some manufacturers also provide information about the tile’s suitability for specific applications, like flooring, walls, or countertops.

Q: Where can I find ceramic tile companies in my area?

You can search online directories, browse home improvement stores, or consult local design professionals for recommendations. Many ceramic tile companies have websites where you can view their products and contact them for information.

Ceramic Tile Company Designs And Makes Floor Tiles

Conclusion

Ceramic tile companies play a crucial role in shaping the aesthetics and functionality of our living spaces. From initial inspiration to the final product, they are involved in every step of the tile creation process, utilizing their design expertise and manufacturing prowess to create durable, beautiful, and innovative flooring solutions. Understanding their processes and the trends shaping the industry empowers us to make informed choices when selecting ceramic tiles, ensuring we create spaces that reflect our unique style and meet our specific needs.

Are you interested in learning more about the intricacies of ceramic tile design and manufacturing? Let us know your thoughts in the comments below!