Remember that time you needed to change your tire, and you got stuck trying to lift the car with a wobbly, rusty floor jack? Those frustrating moments are a testament to the importance of maintaining your tools – especially heavy-duty ones like a floor jack. A Craftsman 3 1/2 ton floor jack, with its reliable lifting capacity, is an essential addition to any garage, but like all machines, it requires regular care and attention. This article will explore the various parts of the Craftsman 3 1/2 ton floor jack, providing insights into their role and how to identify potential issues. We’ll also dive into essential maintenance tips and shed light on where to source replacement parts if needed.

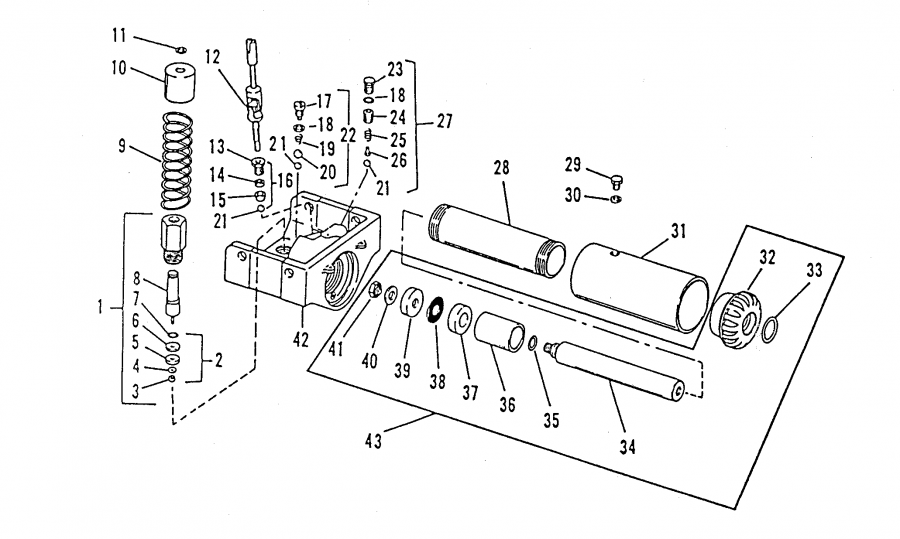

Image: oneseds.blogspot.com

While the Craftsman 3 1/2 ton floor jack might seem like a simple tool, understanding its internal workings is crucial for ensuring its longevity and performance. From the hydraulic pump to the release valve, each component plays a vital role in the lifting and lowering mechanism. Recognizing potential problems early on can save you time, effort, and money in the long run, keeping you prepared for any automotive maintenance needs.

Understanding the Craftsman 3 1/2 Ton Floor Jack: A Closer Look

A Craftsman 3 1/2 ton floor jack is a hydraulic tool designed to lift vehicles safely and efficiently. Its robust construction and reliable lifting capabilities make it a popular choice for DIY enthusiasts and professionals alike. But what exactly makes this jack tick?

Essential Components:

The Craftsman 3 1/2 ton floor jack comprises several key components that work in harmony to execute the lifting and lowering functions.

- Pump Handle: The handle is the primary interface for operating the jack. Pumping it activates the hydraulic system, forcing fluid into the jack cylinder and lifting the vehicle. It allows precision control, enabling incremental lifting.

- Hydraulic Cylinder: This is the heart of the jack, a sealed cylinder containing hydraulic fluid. When the pump handle is operated, fluid is forced into the cylinder, extending a piston that lifts the vehicle.

- Lifting Arm: The lifting arm is connected to the piston and extends outwards, providing a stable platform to support the vehicle. It’s typically made from robust materials to ensure stability.

- Release Valve: This valve controls the release of hydraulic fluid from the cylinder, lowering the vehicle. It allows for controlled descent and prevents sudden drops.

- Base: The wide base provides stability and distributes the weight of the jack and the lifted vehicle. A reinforced base ensures long-lasting performance and prevents wobbliness.

- Saddle: The saddle is the part that rests on the vehicle, securely lifting it from the ground. It’s often equipped with a rubber pad to prevent damage to the vehicle’s undercarriage.

Common Issues and Troubleshooting: Keep Your Jack in Top Shape

Like any mechanical device, the Craftsman 3 1/2 ton floor jack can experience wear and tear over time. Understanding the common issues and their causes will enable you to troubleshoot effectively and keep your jack in top working condition. Here are some typical problems and possible solutions:

Image: flavored.ph

Slow or No Lift:

If your jack isn’t lifting as quickly as it used to or isn’t lifting at all, several factors could be at play. A primary culprit could be low hydraulic fluid levels. The jack needs adequate fluid to operate efficiently. Check the fluid level, and if low, top it up with the appropriate hydraulic fluid.

Leaking Hydraulic Fluid:

A leaking jack can lead to a loss of lifting capacity and pose a safety hazard. Inspect the hose connections, seals, and cylinders for any fluid leakage. If you spot any leaks, try tightening the connections or replacing worn seals. If the leaks persist, seek professional assistance.

Slow Lowering:

A sluggish lowering mechanism could indicate a problem with the release valve. If it’s not functioning correctly, it might prevent the hydraulic fluid from being released smoothly. This can be addressed by cleaning the valve or replacing it entirely, if necessary.

Wobbling Base:

A wobbly base can be caused by damage to the base structure, worn wheel bearings, or loose components. Inspect the base for cracks or damage, check the wheel bearings for free movement, and ensure all screws and bolts are securely tightened.

Saddle Damage:

The saddle is crucial for lifting the vehicle safely. Inspect it for signs of wear, cracks, or dents. If worn or damaged, it could affect the stability of the lift. Consider replacing it to ensure continued safety and stability during lifting operations.

Maintenance Tips for a Smooth Lift: Keeping Your Jack Ready

Maintaining your Craftsman 3 1/2 ton floor jack is key to ensuring a smooth lifting experience. Regular checks and basic maintenance can prevent unexpected problems and extend the life of your jack.

- Check Hydraulic Fluid Level: Regularly inspect the fluid level and top it up if necessary. Use the appropriate type of hydraulic fluid, as recommended by the manufacturer.

- Inspect for Leaks: After each use, carefully examine the jack for any leaks. Address any leaks promptly to prevent further damage and fluid loss.

- Clean Regularly: Dust and dirt can accumulate on the jack, hindering its smooth operation. Regularly clean the jack with a soft brush or cloth, removing any debris.

- Lubricate Moving Parts: Parts like the pump handle, release valve, and wheel bearings should be lubricated with a suitable lubricant to ensure smooth operation.

- Store Correctly: When not in use, store the jack in a clean, dry place to prevent corrosion and damage.

Finding Replacement Parts: Ensuring Long-Term Performance

Should your Craftsman 3 1/2 ton floor jack require replacement parts, several options are available. You can start with the Craftsman website or an authorized retailer for genuine parts.

If you are facing difficulties obtaining the specific part from Craftsman, alternative resources include online marketplaces, automotive supply stores, and specialized tool retailers. Be sure to cross-reference the part numbers and specifications to ensure compatibility, and choose parts from reputable sources for optimal quality and performance.

FAQs About Craftsman 3 1/2 Ton Floor Jacks

Q: How often should I check the hydraulic fluid level?

It’s best to check the fluid level before each use, especially if the jack hasn’t been used for a prolonged period. This will ensure that the jack is adequately lubricated and functioning properly.

Q: What type of hydraulic fluid should I use?

Consult your Craftsman 3 1/2 ton floor jack’s user manual or contact the manufacturer for specific recommendations on the type of hydraulic fluid to use. Using the correct fluid is essential for optimal performance and longevity.

Q: Can I repair the jack myself?

For basic maintenance like fluid checks, cleaning, and lubrication, you can handle the repairs yourself. However, for more complex issues like leaks, release valve problems, or structural damage, it’s recommended to seek professional assistance from a qualified mechanic or tool repair specialist.

Q: How long does a floor jack last?

A well-maintained Craftsman 3 1/2 ton floor jack can last for years. The lifespan depends on the frequency of use, storage conditions, quality of maintenance, and the severity of any issues. Regular checks, proper care, and timely repairs can extend its lifespan significantly.

Craftsman 3 1 2 Ton Floor Jack Parts

Conclusion: Keeping Your Craftsman Jack Lifting for Years

Understanding the inner workings of your Craftsman 3 1/2 ton floor jack and practicing regular maintenance can extend its lifespan and ensure trouble-free operation. With the right care and attention, your jack will continue to be a reliable tool for years to come. So, are you ready to keep your jack in peak condition and avoid those frustrating “stuck” moments? By following the tips and insights shared in this article, you’ll be well-equipped to ensure a smooth lift every time.