Have you ever stared into a toolbox, overwhelmed by the sheer variety of wrenches and tools, wondering what the difference is between a socket wrench and a ratchet? It’s a common dilemma for even experienced DIYers. Both tools are essential for twisting nuts and bolts, but each has its own unique advantages and limitations. This comprehensive guide will delve into the world of socket wrenches and ratchets, exploring their individual strengths, how they differ, and ultimately help you choose the perfect tool for your needs.

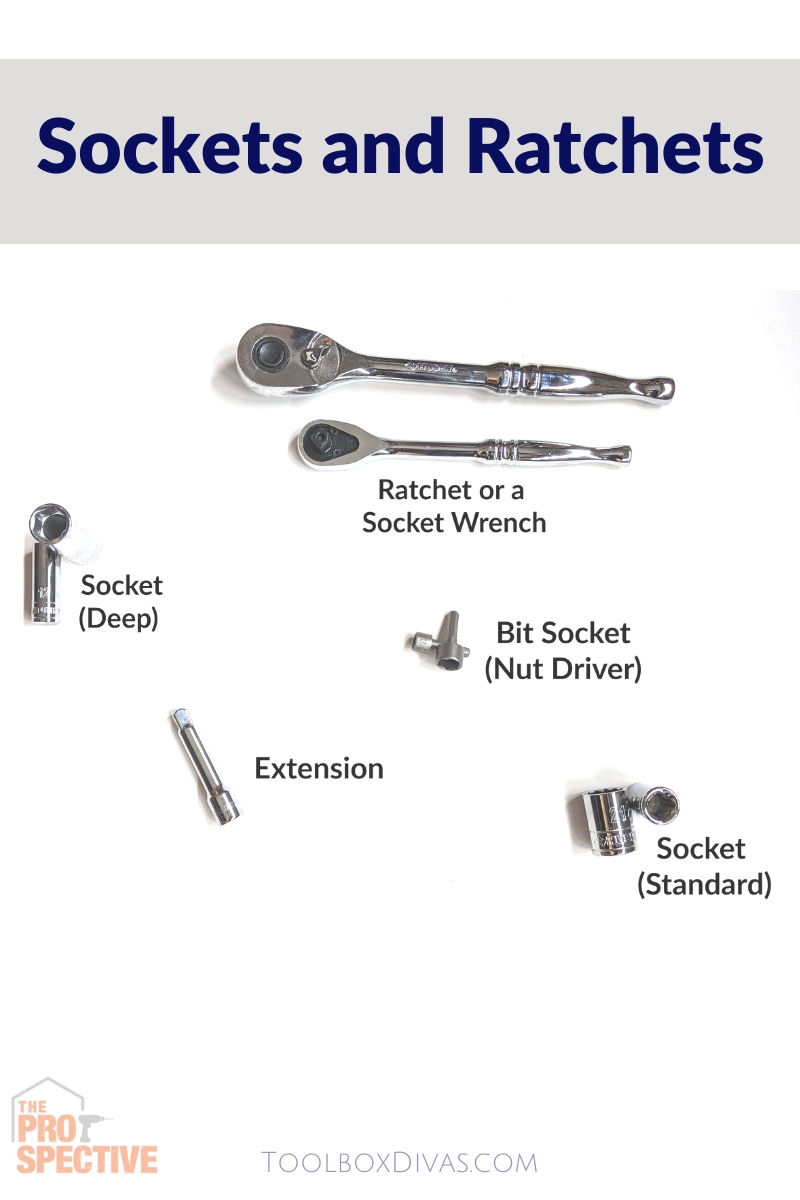

Image: toolboxdivas.com

Whether you’re tackling a home repair project, working on your car, or simply want to understand the tools in your garage better, understanding the differences between socket wrenches and ratcheting wrenches lays the foundation for efficient, effective, and sometimes even enjoyable work. We’ll answer questions like: What makes a socket wrench different from a ratchet? Which tool is better for a specific task? Are there hybrid tools combining the best of both worlds? Let’s dive into the fascinating world of mechanical leverage and discover the power of these essential hand tools.

The Definition and Essential Components

Socket Wrench: The Power of Precision and Adaptability

A socket wrench, often called a “socket set,” is a versatile tool that uses interchangeable sockets to grip fasteners of different sizes. It consists of several core components:

- Socket: A hollow, hexagonal (or sometimes square or spline) piece that fits over the nut or bolt head. Sockets come in a wide range of sizes to accommodate different fasteners.

- Drive: The mechanism that connects the socket to the handle, typically a square or hexagonal opening that matches the drive size of the socket.

- Handle: The lever that provides torque (twisting force) when turning the socket.

Socket wrenches are known for their precision and the ability to apply significant torque to stubborn fasteners. They’re also adaptable, allowing you to tackle various tasks with a single wrench by simply switching out the socket.

Ratchet Wrench: Smooth and Efficient Turning

A ratchet wrench, in its simplest form, is a wrench with a ratcheting mechanism that allows you to turn a fastener in one direction without having to remove the wrench from the nut or bolt. This makes it extremely efficient for repeated, controlled tightening or loosening of fasteners, especially in tight spaces.

A ratchet wrench typically has a handle with a ratcheting mechanism inside. This mechanism allows the handle to move in one direction while locking in the other. The ratchet head engages with the fastener, providing the turning force.

Image: www.mbpradom.pl

Comparing the Pros and Cons

Socket Wrench – Pros & Cons

Socket wrenches excel in situations where you need to apply high torque or versatility in fastener size. Here’s a closer look:

Pros:

- High Torque: Socket wrenches provide high leverage, enabling you to loosen or tighten even the most stubborn fasteners.

- Versatility: The ability to swap sockets allows you to work on fasteners of various sizes with a single tool.

- Durability: High-quality socket wrenches are durable and can handle heavy-duty applications.

Cons:

- Bulkier: Socket wrenches are often bulkier than ratchet wrenches, making them less ideal for tight spaces.

- Storage Concerns: A socket wrench set often requires more storage space than a single ratchet wrench, especially if you need a wide range of socket sizes.

Ratchet Wrench – Pros & Cons

Ratchet wrenches shine in situations where you need to make quick, repeated turns within confined spaces.

Pros:

- Efficiency: The ratcheting mechanism allows for quick, repetitive turning without removing the wrench from the fastener, saving time and effort.

- Compact: Ratchets are typically more compact than socket wrenches, making them ideal for tight spaces and awkward angles.

- Ease of Use: Ratchet wrenches are generally easier to use than socket wrenches, especially for beginners.

Cons:

- Lower Torque: Typically, ratchet wrenches can’t generate as much torque as socket wrenches.

- Limited Size Range: A single ratchet wrench is generally limited to a specific size fastener, unlike socket wrench sets.

Choosing the Right Tool for the Job

The best tool for a task depends on the specific situation. Consider these factors:

- Fastener Size: If you’re working with a variety of fastener sizes, a socket wrench set provides the best flexibility.

- Torque Requirement: If you need to apply high torque, a socket wrench is the better choice. For light-duty tasks, a ratchet may be sufficient.

- Space Constraints: For tight spaces, a ratchet wrench is a more compact and maneuverable option.

- Frequency of Use: If you’re frequently working with the same size fastener, a single ratchet wrench may be the most efficient option.

For example, when rebuilding an engine, a socket wrench set is indispensable due to the high torque needed for tightening engine bolts and the variety of sizes required for different components. However, when installing a light bulb, a simple ratchet wrench is more than sufficient and much easier to maneuver in tight spaces.

Hybrid Options: Combining the Best of Both Worlds

The lines between socket wrenches and ratchet wrenches have blurred with the advent of hybrid tools that combine the best features of both. These include:

- Ratcheting Socket Wrenches: These tools feature a ratcheting mechanism within the socket itself, allowing for quick and efficient tightening or loosening of fasteners.

- Socket Wrenches with Ratcheting Handles: These tools integrate a ratcheting handle onto a standard socket wrench, offering the benefits of both.

These hybrid tools provide a great balance of torque, versatility, and ease of use. For example, a ratcheting socket wrench is perfect for working on car repairs where quick action and a mix of fastener sizes are common.

Beyond Basic Tools: Special Considerations

The world of socket wrenches and ratchets extends beyond the basic models. Some specialized tools, like torque wrenches, provide even greater precision and control.

- Torque Wrenches: These wrenches allow you to precisely control the amount of torque applied to a fastener, preventing over-tightening and potential damage. Torque wrenches are crucial in applications where precise tightening is critical to prevent component failure, such as engine repair.

- Impact Wrenches: Power tools designed for high-torque applications, like tire changing. Impact wrenches use an internal hammering mechanism to loosen or tighten fasteners very quickly.

- Breaker Bars: Extra-long socket wrenches designed for loosening extremely tight fasteners where extra leverage is needed.

The Future of Socket Wrenches and Ratcheting Wrenches

The world of wrenches continues to evolve. Advanced materials like lightweight composites and innovative designs like modular socket systems are making these tools even more versatile and efficient.

Here are some exciting possibilities on the horizon:

- Smart Wrenches: Wrenches that utilize sensors and wireless communication to monitor torque applied, provide real-time feedback, and even connect to apps for data logging.

- Modular Socket Systems: Sophisticated systems that allow users to easily customize wrench heads with different socket sizes and drive types.

- 3D-Printed Wrenches: The ability to custom-print wrenches on demand, potentially solving specific needs or creating unique designs.

These advancements promise to make working with wrenches even easier, faster, and more accurate than ever before.

Socket Wrench Vs Ratchet

Conclusion: The Power of Choice

Ultimately, choosing the right wrench boils down to understanding your needs and the specific task at hand. Whether you opt for a traditional socket wrench, a trusty ratchet, or a hybrid solution, these versatile tools are essential for countless tasks.

Armed with this knowledge, you’re ready to tackle any project with confidence. Remember, the right tool can make all the difference in the world. Happy wrenching!