Have you ever found yourself faced with a daunting task of securing something heavy to a concrete surface? I certainly have. Whether it’s hanging a heavy swing set in your backyard, mounting a sturdy shelf in your garage, or installing a brand-new patio, the right anchor can make all the difference. But deciphering the world of anchors, particularly wedge and sleeve anchors, can feel like a confusing maze. And that’s where the excitement starts – understanding the distinct advantages and limitations of wedge and sleeve anchors can unlock the secret to successful, worry-free installations.

Image: factorydirectsupplyonline.com

In this comprehensive guide, we’ll embark on a journey to fully dissect wedge and sleeve anchors. We’ll explore their unique features, delve into their applications, and discuss the crucial factors to consider when choosing between these two popular anchor types. So, grab your tool belt, let’s dive in!

Wedge Anchors: Expanding for Strength

Unveiling the Wedge Anchor

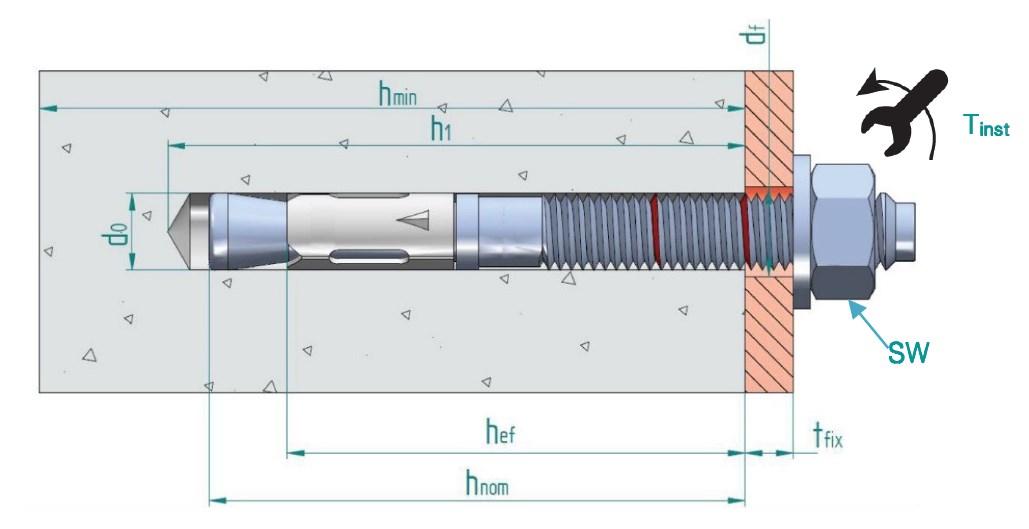

Imagine a small, cleverly designed wedge that’s driven into a pre-drilled hole in concrete. As you tighten the screw, this wedge cleverly expands outwards, creating a strong and secure grip. That’s the essence of a wedge anchor – a simple yet ingenious mechanism that provides robust anchoring solutions for a wide range of applications. They’re often preferred for handling heavy loads due to their impressive holding strength.

The Working Principle of Wedge Anchors

Wedge anchors are typically composed of a metal sleeve with a wedge-shaped element inside. When a screw is driven into the anchor, the wedge is forced outward, expanding against the walls of the drilled hole. This expanding action generates friction and creates a strong grip, firmly securing the anchor within the concrete. The principle of the wedge anchor is based on the concept of mechanical expansion, relying on outward force to generate a secure hold.

Available in various materials like steel, stainless steel, and zinc-plated steel, they are known for their resistance to corrosion and durability.

Image: www.fasten.com.sg

Sleeve Anchors: A Secure Grip for Various Projects

Sleeve Anchor: A Detailed Look

Sleeve anchors, often called expansion anchors, are another common and effective anchoring solution. Think of these as hollow tubes that are placed in a pre-drilled hole in the concrete. As you drive in a screw or bolt, the sleeve expands outward, firmly clamping onto the walls of the hole. This expanding action effectively secures the anchor within the concrete, providing a strong and reliable anchor point.

The Mechanics of Sleeve Anchors

Sleeve anchors work by utilizing a simple yet effective principle: expansion. When you drive the screw or bolt into the anchor, the sleeve’s internal design allows it to expand outwards. This expansion process creates friction against the walls of the drilled hole, producing a secure grip. The sleeve anchor’s ability to expand effectively anchors it in place, making it ideal for a variety of applications, from light-duty projects to heavy-duty installations.

Sleeve anchors are generally available in a range of materials like steel, stainless steel, plastic, and nylon, offering diverse resistance levels to corrosion and varying load capacities.

Wedge vs Sleeve Anchor: Making the Right Choice

Understanding the Key Differences

Now that we’ve delved into the mechanics of both types of anchors, let’s explore the key differences that can help you decide which one is best for your project:

| Feature | Wedge Anchor | Sleeve Anchor |

|---|---|---|

| Expansion Mechanism | Wedge expands outwards, generating friction | Sleeve expands outwards, generating friction |

| Load Capacity | Generally higher, as wedges typically have higher holding power | Varies based on material and size, generally suitable for moderate to heavy loads |

| Installation | Requires pre-drilling a hole slightly larger than the anchor’s diameter | Requires pre-drilling a hole slightly larger than the anchor’s diameter |

| Materials | Available in steel, stainless steel, zinc-plated steel | Available in steel, stainless steel, plastic, nylon |

| Cost | Typically more expensive than sleeve anchors | Typically more affordable than wedge anchors |

| Applications | Heavy-duty applications, structural mounting, high-load bearing requirements | Broad range of applications, including light to moderate loads, general purpose anchoring |

Factors to Consider

Choosing between wedge and sleeve anchors fundamentally boils down to the specific demands of your project. Here’s a helpful breakdown of key factors to consider:

- Load Capacity: If your project involves heavy loads, wedge anchors are often the preferred choice due to their superior holding power.

- Material Selection: Evaluate the conditions of the environment where you’ll be using the anchor. For areas prone to moisture or corrosion, stainless steel anchors might be your best bet.

- Budget: Wedge anchors tend to be more expensive than sleeve anchors. If budget is a significant factor, sleeve anchors are a viable alternative for moderate loads.

- Ease of Installation: Both types of anchors require pre-drilling, but the installation process is generally similar.

Expert Tips for Choosing and Installing Anchors

Based on my years of DIY experience, here are some tips to maximize your anchor installation success:

- Always pre-drill: The correct hole size is crucial for proper installation and anchor performance. Use a drill bit slightly larger than the anchor’s diameter, to ensure it fits snugly and expands properly.

- Use a hammer drill: Especially for concrete, a hammer drill helps create cleaner holes with less stress on the anchor.

- Clean the hole: Debris in the hole can interfere with anchor expansion. Before inserting the anchor, ensure the hole is clean and free of dust or debris.

- Tighten gently, gradually: Over-tightening can damage the anchor. Tighten the screw or bolt gradually, ensuring a secure grip without excessive force.

- Double-check the installation: Once you’ve installed the anchor, give it a gentle tug to ensure it’s securely fastened.

Following these guidelines will help you install your anchors correctly, maximizing their strength and ensuring the longevity of your projects.

Frequently Asked Questions (FAQs)

Q: What is the difference between a wedge anchor and a sleeve anchor?

A: Wedge anchors have a wedge-shaped element that expands outward when a screw is driven in, creating a strong grip. Sleeve anchors are hollow tubes that expand outwards as the screw or bolt is driven in, securing the anchor within the hole.

Q: Are wedge anchors stronger than sleeve anchors?

A: Generally, wedge anchors offer greater holding power due to their wedge expansion mechanism, making them suitable for heavier loads. However, the strength of sleeve anchors also varies depending on their size, material, and expansion design.

Q: Can I use wedge or sleeve anchors in any type of concrete?

A: It’s best to consult the anchor’s manufacturer specifications and consider the type of concrete you’re working with. Anchors designed for solid concrete may not perform optimally in cracked or weakened concrete.

Q: How long do wedge and sleeve anchors last?

A: The lifespan of wedge and sleeve anchors varies depending on factors like their quality, installation, and environmental conditions. If properly installed, they can provide long-lasting stability and hold.

Wedge Vs Sleeve Anchor

Conclusion

Understanding the distinct features and applications of wedge and sleeve anchors puts you in control of selecting the right anchor for your projects. Whether you’re tackling heavy-duty installations or general anchoring needs, this guide has provided valuable insights and expert tips to help you make informed decisions and enhance your projects.

Are you ready to tackle your next anchoring project with confidence? Share your thoughts and experiences in the comments section below! Let’s continue the conversation and learn from each other.