Imagine stepping into an elevator, pressing a button, and effortlessly ascending to your desired floor. This seemingly simple act relies on a complex symphony of technology, including the often-unsung hero of the modern world: the Programmable Logic Controller (PLC). In the realm of elevators, PLCs act as the brains, orchestrating every movement and ensuring a safe and smooth journey. Today, we embark on a fascinating journey into the heart of elevator control systems, focusing on the intricate logic behind controlling a 3-floor elevator using PLC ladder logic.

Image: mydiagram.online

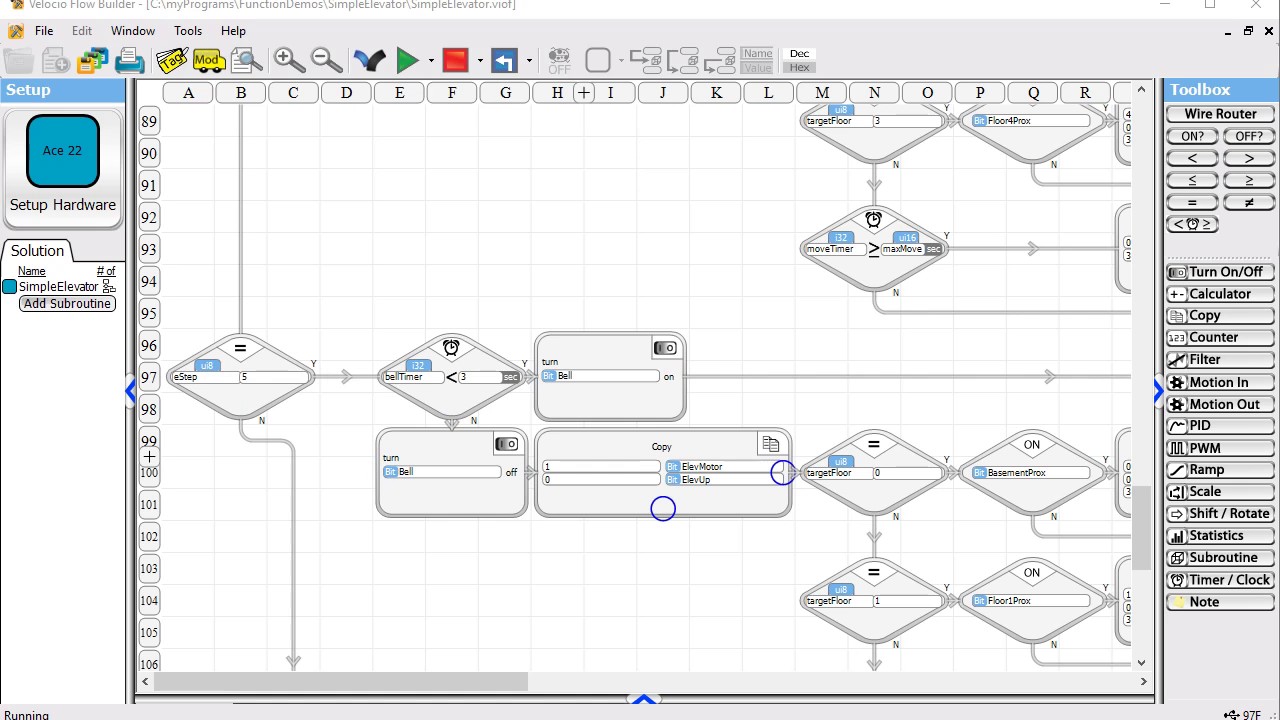

The heart of an elevator control system lies in the PLC program, and within that program, the ladder logic plays a crucial role. Understanding PLC ladder logic is like reading the elevator’s language, deciphering how it responds to different inputs and commands. This intricate system of logic gates, contacts, coils, and timers forms the basis of the elevator’s brain, governing its every move, from starting and stopping to managing safety features and ensuring that the doors open and close smoothly.

Decoding the Language of Ascent: A Step-by-Step Guide

For those new to the world of PLCs, the concept of ladder logic might seem intimidating, resembling a peculiar code that evokes images of ancient circuitry. But fear not! The essence of ladder logic is surprisingly straightforward: it mimics the visual representation of electrical circuits, simplifying complex control systems into a more intuitive format. It’s like a flowchart that describes the intricate dance of electrical signals within the system.

The Ladder Logic Primer:

- Ladder Rungs: Imagine each rung in a ladder as a single command or instruction within the PLC program. These rungs are the individual threads that weave together the intricate tapestry of elevator control.

- Contacts: Just like switches in a traditional electrical circuit, contacts in ladder logic represent conditions that can be either open or closed. They are the ears of the system, listening for signals like button presses, floor sensors, and safety interlocks.

- Coils: Coils represent the actions of the system, akin to actuators in an electrical circuit. They respond to signals from the contacts, triggering actions like activating motor control, opening doors, or illuminating indicator lights.

- Timers: Timers play a crucial role in controlling the duration of actions, ensuring that door closures are synchronized, safety delays are implemented, and the overall operation runs smoothly.

- Counters: Counters keep track of events, such as the number of times a button has been pressed or the number of floors the elevator has traveled. This information is essential for managing traffic and ensuring efficient operation.

Decoding a 3-Floor Elevator Ladder Logic:

- Floor Selection: The journey begins with the passenger’s choice: a push of a button on the control panel. This action closes the corresponding button contact, signifying the desired floor.

- Door Open/Close Control: The PLC ladder logic then checks for the appropriate condition to open or close the elevator door. This typically involves a combination of floor sensors signaling the elevator’s arrival at the correct floor and a timer that ensures adequate time for passengers to enter or exit.

- Motor Control Logic: To initiate movement, the PLC determines the direction of travel based on the difference between the current floor and the selected floor (up or down). The ladder logic then manages the motor control signal, determining the speed and direction of the lift.

- Floor Sensor Feedback: As the elevator travels, floor sensors provide constant feedback to the PLC, notifying it of the elevator’s position. This input is vital for determining the next move, whether it’s stopping at the selected floor, continuing travel, or engaging safety features.

- Safety Interlocks: The heart of the system beats with safety. Numerous interlocks are constantly monitored by the ladder logic, interrupting or modifying operation in case of emergencies or potential hazards. This could include things like preventing movement if the elevator doors are ajar, halting the lift in case of excessive speed, or triggering an alarm if the cable tension is compromised.

Beyond the Code: Mastering the Art of Elevator PLC Logic

Understanding the principles of PLC ladder logic for a 3-floor elevator is a valuable stepping stone for grasping the intricacies of more complex systems. It’s a foundation upon which you can build your knowledge and delve deeper into the realm of sophisticated control systems.

Tips for Mastering the Art:

- Visualize the Logic: Think of the ladder logic as a visual representation of the elevator’s actions. Visualize the flow of signals and the logic involved, creating a mental model of the system.

- Start Small: Begin with simple examples, gradually increasing the complexity of the systems you analyze. Understanding a 3-floor elevator can serve as a stepping stone to more intricate systems with multiple floors and advanced features.

- Practice Makes Perfect: The key to mastering PLC ladder logic lies in hands-on experience. Try simulating different scenarios, experimenting with various input conditions, and observing how the ladder logic responds.

- Embrace Resources: The realm of PLC programming is vast and diverse. Leverage online resources, tutorials, and documentation to deepen your understanding.

Unlocking the Future of Motion: The Evolution of Elevator Control Systems

As technology evolves, so too do elevator control systems. The age of digital controllers, embedded software, and real-time operating systems is transforming the way elevators are designed and operated. Today, we see systems that leverage advanced algorithms for energy efficiency, intelligent traffic management, and even the ability to predict potential failures before they occur. This evolution is driven by the relentless pursuit of safety, efficiency, and user comfort, making the elevator ride a seamless and intuitive experience.

The Future of Vertical Mobility:

- Artificial Intelligence (AI): AI is poised to play an increasingly transformative role in elevator control, enabling smarter traffic management, predictive maintenance, and personalized user experiences.

- Internet of Things (IoT): The integration of IoT principles allows for remote monitoring, real-time data analysis, and optimized system performance.

- Advanced Safety Features: From predictive maintenance to real-time collision avoidance systems, advanced safety features are being developed to further enhance safety and reliability.

Image: www.youtube.com

3 Floor Elevator Plc Ladder Logic Pdf

https://youtube.com/watch?v=-qreRfbqC60

The Ascent Continues: A Final Word

The seemingly simple act of pressing a button in an elevator conceals a world of intricate technology and precise engineering. By understanding the principles of PLC ladder logic, we unlock a deeper appreciation for the systems that shape our daily lives. From the humble 3-floor elevator to the towering skyscrapers of the future, the magic of elevator control continues to evolve, promising a smoother, safer, and more intelligent journey to the top.