Have you ever walked into a room and caught a glimpse of a steel cable lying flat on the floor, seemingly dragging itself across the surface? It’s a strange sight, a metallic serpentine slithering across the smooth expanse, leaving one to wonder – what in the world is going on?

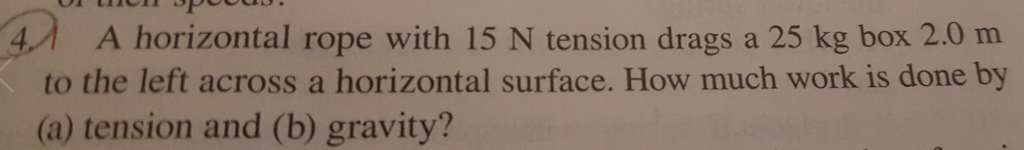

Image: www.chegg.com

This seemingly impossible phenomenon is actually a common yet often overlooked occurrence, a consequence of the laws of physics and the subtle forces acting upon the cable. Understanding why a steel cable drags on the floor requires diving into the realm of friction, tension, and the delicate balance between these forces.

The Physics Behind the Drag

Friction: The Force that Opposes Movement

The primary culprit behind the dragging steel cable is friction, the force that resists motion between two surfaces in contact. When a solid object, such as our steel cable, rests on a surface like a floor, the microscopic irregularities of both surfaces interlock, creating a resistance to movement. This resistance, known as friction, acts as a barrier, opposing any attempt at sliding or dragging.

Tension: A Tale of Two Ends

The story doesn’t end with friction alone. The steel cable, by its very nature, is designed to withstand tension, a force that pulls on the object from opposite ends. This tension is often present in cables, whether they’re used for suspension bridges, elevators, or even simple household appliances.

Imagine a cable lying flat on the floor. Now imagine pulling on one end of the cable. The tension generated creates a pulling force that attempts to move the cable. But friction, as we know, acts against this movement, creating a standoff between the pulling force and the resisting force.

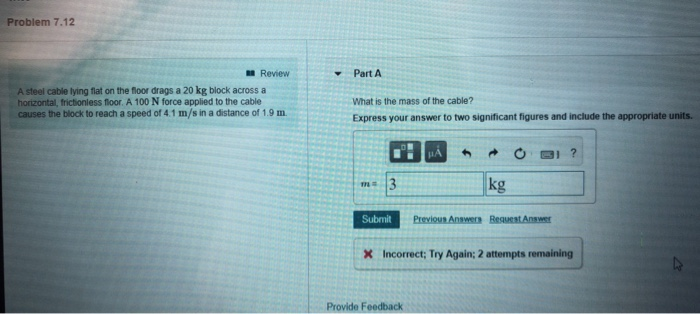

Image: www.chegg.com

The Balancing Act

The drama unfolds when the tension force overcomes the frictional force. As the tension increases, the pulling force on the cable becomes stronger, eventually exceeding the resistance offered by friction. This is the moment the cable starts to drag—it yields to the tension force and begins to slide across the floor.

The dragging we witness is not a constant motion. It’s a dynamic interplay between friction and tension. The cable might start to move, then slow down as the frictional force increases due to the cable’s increased contact with the floor. It might even stop momentarily, only to resume its journey as the tension force regains its dominance. It’s a continuous, intricate dance of opposing forces.

Real-World Scenarios

This dragging phenomenon is not limited to the isolated scenario of a cable lying flat on the floor—it’s a common reality in many applications.

Industrial Applications

In industrial settings, steel cables are often used for hoisting heavy loads. As the load is lifted, the cable stretches, creating tension. If the load is lowered slowly, the tension reduces, and the cable can sometimes drag against the surface it’s running on, such as a pulley or a drum. This dragging can cause wear and tear on the cable, leading to potential safety concerns.

Marine Applications

Marine applications, such as anchor chains, also demonstrate the dragging effect. When a ship’s anchor is being raised, the chain has to be pulled up against the resistance of the seabed. Depending on the chain’s length, the tension may be high enough to cause the chain to drag on the seabed, creating a dragging sound as the ship maneuvers itself away from the anchor.

Construction Applications

In construction projects, steel cables are used in various ways—for lifting heavy equipment, securing structures, and even creating temporary walkways. When these cables are in use, they often encounter surfaces, including beams, concrete slabs, and even soil. If the tension in the cable fluctuates, it can lead to dragging against the surface, causing wear and tear on the cable itself or the supporting structures.

Mitigating the Dragging Effect

While the dragging of a steel cable is a natural consequence of the forces at play, there are methods to minimize or even eliminate the effect.

Lubrication

Applying lubrication to the surfaces in contact can significantly reduce the friction between the cable and the surface. Oils, greases, and other lubricants reduce the friction by creating a thin layer between the surfaces, allowing the cable to slide more freely.

Reducing Tension

By lowering the tension in the cable, the pulling force is reduced, making it easier for friction to hold the cable in place. In industrial settings, this can be achieved by adjusting the load being lifted or the speed at which it’s being moved.

Proper Cable Handling

Carefully handling the cable and ensuring it’s properly secured can also minimize dragging. For instance, using pulleys with smooth surfaces or ensuring the cable is coiled correctly can prevent snags and the accumulation of friction.

A Steel Cable Lying Flat On The Floor Drags

https://youtube.com/watch?v=SCxqg264kkk

Conclusion

The seemingly simple act of a steel cable dragging across the floor reveals a complex interplay of physical forces. Understanding these forces, their interplay, and the real-world implications is crucial in various applications, from industrial settings to marine environments and construction projects. While the dragging effect is a natural phenomenon, recognizing its causes and learning to mitigate it through lubrication, tension management, and proper handling can significantly improve safety, efficiency, and the longevity of any structure or system reliant on steel cables.